Happy Thanksgiving and Embroidery Holds!!!

Greetings everyone…

It is hard for me to believe Thanksgiving is right around the corner but here we are again. The next five to six weeks is usually the busiest time of the year for all of us at the “Q” and as we prepare to dig in for the Holiday push I want to take a moment to thank each and every one of you for your continued support in our products and services. Seriously, thank you. Without you Qdigitizing is just a good idea and bunch of computers.

As almost all of you know Qdigitizing is a Next Business Day service for all digitizing orders that will fit inside a 6” circle. However, our internal time clock does not start until we have all of the information we need to start a design. We receive designs all day long and then we schedule those orders to be programmed during our night shift. Unless you have selected Same Day Service your design will not be reviewed by a programmer until the design is assigned. At that point if we do not have enough information to proceed or if what has been requested will not (in our opinion) allow for quality embroidery we will put the order ON HOLD and send you a message requesting instructions for how we can proceed. Once we have that information we become a “Next Business Day Service.” Below I am going to show several designs that have been on hold with an explanation for the design was put on hold. If you are in a time crunch for having your projected completed and you have any doubt about the “embroider-ability” of your art please email us with your image and instructions BEFORE you submit your order so Flora or myself can reach out to you and prevent a Hold Delay on your order.

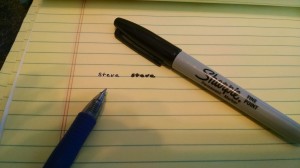

I would estimate that fully 90% of orders are put On Hold due to issues with text. What must be understood is embroidery simply does not have the resolution of other print mediums. I want you to do a simple test for me that will help drive this point home. Take any ball point pen you have and print your name as small as you can so you can read it. Now I want you to go find a “fine point” Sharpie, print your name and compare the results.

The image you see here is very illustrative of the challenge we have. Print and Display resolution are like the pen of the left while embroidery resolution is like the sharpie on the right. As you can see with the Sharpie name, the S and the E’s fill while the T and V look blotchy. It is the same thing with thread. The absolute minimum size for any embroidery design element is the thickness of one thread or roughly 1mm. There is no physical way to make any line any more narrow than the width of a thread. As a result and especially with lettering and very fine detail the smaller a design element becomes the more difficult it becomes to embroidery with a high degree of clarity.

is very illustrative of the challenge we have. Print and Display resolution are like the pen of the left while embroidery resolution is like the sharpie on the right. As you can see with the Sharpie name, the S and the E’s fill while the T and V look blotchy. It is the same thing with thread. The absolute minimum size for any embroidery design element is the thickness of one thread or roughly 1mm. There is no physical way to make any line any more narrow than the width of a thread. As a result and especially with lettering and very fine detail the smaller a design element becomes the more difficult it becomes to embroidery with a high degree of clarity.

The result of this reality is digitizers have to modify your art to work in our medium. We do this on virtually 100% of the art receive it just that it is much more apparent on some designs than others.

This first example is a beautiful design for screen display and print but if this were to be embroidered at the size requested the fine detail lines around the large letters would need to be programmed as walk stitches and the outline you can barely see around the bottom letters cannot be done at all, no matter what. The problem with walk stitch borders is many “end users” don’t like how they sometimes look like a “dashed line” instead of a nice smooth line like a satin stitch. The problem here is if we program the detail stitches as satin stitches they become virtually the same width as the main letter and it doesn’t look, “right” and the inside portions of letters like the R’s A and inside corners of E’s an Y would fill in. If we enlarge the design to maintain the proportions and correct for the fill in the image would become far too large for traditional left chest embroidery. We can program the detail with a walk stitch and technically it will be fine but whether or not the design is accepted from a subjective/cosmetic standpoint will depend entirely on you and your customer.

This first example is a beautiful design for screen display and print but if this were to be embroidered at the size requested the fine detail lines around the large letters would need to be programmed as walk stitches and the outline you can barely see around the bottom letters cannot be done at all, no matter what. The problem with walk stitch borders is many “end users” don’t like how they sometimes look like a “dashed line” instead of a nice smooth line like a satin stitch. The problem here is if we program the detail stitches as satin stitches they become virtually the same width as the main letter and it doesn’t look, “right” and the inside portions of letters like the R’s A and inside corners of E’s an Y would fill in. If we enlarge the design to maintain the proportions and correct for the fill in the image would become far too large for traditional left chest embroidery. We can program the detail with a walk stitch and technically it will be fine but whether or not the design is accepted from a subjective/cosmetic standpoint will depend entirely on you and your customer.

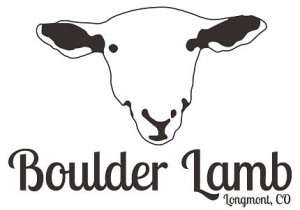

This second example is very typical of a request we will receive. This design is requested for caps. That means the maximum height for most of you is 2.25” some can go up to 2.5” but with this design it would not matter. When this design is reduced to cap size the small Longmont, CO will not be embroider-able, period. The letters will be far too small, even programmed as a walk stitch. There is nothing we can do about this unless the end user is willing to either delete this lettering entirely or agree to move the lettering to a different location in the design and allows us to make the lettering larger and out of proportion to the rest of the design.

This second example is very typical of a request we will receive. This design is requested for caps. That means the maximum height for most of you is 2.25” some can go up to 2.5” but with this design it would not matter. When this design is reduced to cap size the small Longmont, CO will not be embroider-able, period. The letters will be far too small, even programmed as a walk stitch. There is nothing we can do about this unless the end user is willing to either delete this lettering entirely or agree to move the lettering to a different location in the design and allows us to make the lettering larger and out of proportion to the rest of the design.

The final sample for today is very similar in issue to the second. I offer this because we received these orders one immediately after the other. At the requested design size it will not be possible to “cleanly” embroider the letters Sales and Service and NSCL #0057590. Aside from the fact the letters will be too small to embroider nicely what will happen is the letters will distort the small, thin lines that are underneath them. There is nothing we can do about the “physics” of this reality. If it is possible to convoice the user to delete this feature they would wind up with a much nicer design. If the buyer insists the feature must be included maybe they can be talked in to putting this inforamtion under the design or better yet, on the sleeve.

The final sample for today is very similar in issue to the second. I offer this because we received these orders one immediately after the other. At the requested design size it will not be possible to “cleanly” embroider the letters Sales and Service and NSCL #0057590. Aside from the fact the letters will be too small to embroider nicely what will happen is the letters will distort the small, thin lines that are underneath them. There is nothing we can do about the “physics” of this reality. If it is possible to convoice the user to delete this feature they would wind up with a much nicer design. If the buyer insists the feature must be included maybe they can be talked in to putting this inforamtion under the design or better yet, on the sleeve.

My point is not to beat anyone up on the art they submit. Rather, I want to educate my customers so we can help them better understand the challenges we all face in this industry. We all know that the faster we can turn an order the faster we can all get paid. We also know that custoemrs are for more demanding than they used to be. When I started in this busioess 10 days was considered a rush order. Now, for many people 2 and 3 day service is standard and rush is next day. IF you are working in a HOT MARKET environemnt you can help us better help you by getting in front of these issues before they become a time drain for you. Please remember, Qdigitizing cannot start a design until we know how to proceed. WE cannot take it upon ourselves to make wholesale correctiosn to your art. If we run into an issue which requires addional infomrtion we will be forced to put your order On Hold. We don’t want to…I swear, but we can’t just wing it.

IF you all would lie to see more examples like this with an explanation of why the files will ot work please drop me a line here or steve.freeman@qdigitzing.com and I will make this an ongoing series of Do’s and Don’ts for submitting embroidery orders.

No matter what I look forward to hearing from each and everyone of you. PLease drop me a line here or at the work email.

If I don’t get a chance to speak or email with you in the next week or so I hope you will have a warm and wonderful Thanksgiving with your friends and family.

Steve Freeman

steve.freeman@qdigitizing.com

602-228-3830

Hi Steve,

Please do make it a series. I am always up for learning new things, especially things that will make my business life easier!

Thanks,

Bonnie

Good Information to know about submitting designs for digitizing. Please keep on doing the “Do’s and Don’ts”. It’s helpful information so that we work as a team for the finished product. Happy Thanksgiving to you and your staff! Always appreciate the great customer service.